How To Remove Chuck From Milling Machine

A milling machine chuck is a necessary tool for holding the workpiece securely in place during the milling process. However, there may come a time when you need to remove the chuck for various reasons, such as cleaning, repairs, or replacing it with a different chuck.

Removing the chuck from a milling machine may seem like a daunting task, but with the right tools and technique, it can be done efficiently and safely. In this article, we will guide you through the step-by-step process of removing a chuck from a milling machine.

Step 1: Safety First

Before you begin the process of removing the chuck, it’s crucial to prioritize safety. Turn off the milling machine and unplug it from the power source to avoid any accidental injuries. Additionally, wear protective gloves and eyewear to protect yourself from any flying debris.

Step 2: Prepare the Necessary Tools

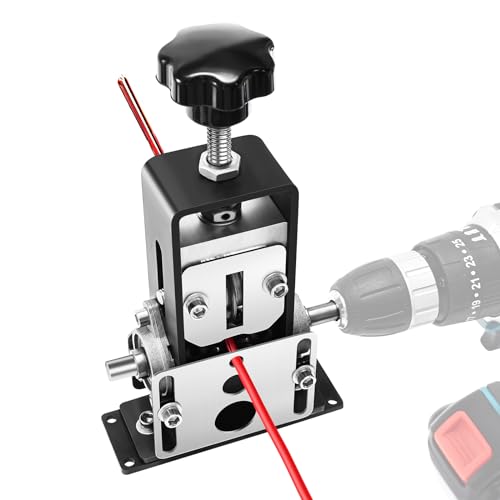

To remove the chuck from the milling machine, you will need a few tools, including an Allen wrench or chuck removal key, a soft mallet, and a screwdriver. Make sure you have these tools readily available before proceeding further.

Step 3: Locate and Unlock the Chuck

Locate the chuck on the milling machine. It is usually positioned at the end of the spindle. The chuck will have a lock or release mechanism that needs to be unlocked before removing it. Insert the Allen wrench or chuck removal key into the lock mechanism and turn it counterclockwise to unlock the chuck.

Step 4: Remove the Chuck

With the chuck unlocked, it is now ready to be removed from the milling machine. Use a soft mallet to tap on the back of the chuck, applying gentle force to loosen it from the spindle. If necessary, you can also use a screwdriver to help pry the chuck off the spindle. Slowly and carefully pull the chuck straight out of the spindle.

Removing the chuck from a milling machine requires patience and precision. It is important to take your time and not rush the process to avoid damaging any parts or causing injury. Once the chuck is removed, you can clean, repair, or replace it as needed before reattaching it to the milling machine.

Conclusion

Removing a chuck from a milling machine may seem challenging, but by following these step-by-step instructions and using the right tools, you can successfully remove the chuck without any hassle. Remember to prioritize safety, take your time, and if you ever feel unsure, consult the manufacturer’s manual or seek professional assistance.

Steps to Remove Chuck From Milling Machine

Removing the chuck from a milling machine can be a straightforward process if you follow the correct steps. Here’s a guide to help you remove the chuck from your milling machine:

- Turn off the machine and unplug it: Before starting any work, ensure that your milling machine is turned off and unplugged. This step is crucial to ensure your safety.

- Secure the spindle: Use a wrench to secure the spindle from rotating. This will prevent any unwanted movement while you’re removing the chuck.

- Remove the retaining bolt: Locate the retaining bolt at the center of the chuck. Use the correct size wrench to loosen and remove the bolt.

- Attach the chuck key: Insert the chuck key into the chuck, ensuring that it engages with the teeth.

- Rotate the chuck counterclockwise: Use the chuck key to rotate the chuck counterclockwise. Apply steady pressure until the chuck becomes loose.

- Remove the chuck by hand: Once the chuck is loose, you can remove it by hand. Carefully lift the chuck off the spindle, making sure not to drop or damage it.

- Clean the spindle: Take the opportunity to clean the spindle thoroughly and remove any debris or dirt that may have accumulated.

By following these steps, you can safely and effectively remove the chuck from your milling machine. Remember to always exercise caution and wear appropriate safety gear while working with machinery.

Preparation

Before attempting to remove the chuck from your milling machine, it is important to gather all the necessary tools and equipment. This will ensure a smooth and efficient removal process. Here is a list of items you will need:

| 1. | A wrench that fits the chuck retaining nut. |

| 2. | A sturdy workbench or table to place the milling machine on. |

| 3. | Safety goggles and gloves to protect your eyes and hands. |

| 4. | A wood block or piece of scrap metal to support the milling machine during chuck removal. |

Once you have gathered all the necessary tools and equipment, make sure you have a clear and well-lit workspace. Remove any obstacles or clutter that might hinder the chuck removal process. It is also recommended to familiarize yourself with the milling machine’s user manual or consult an expert for any specific instructions related to your machine model.

Removing the Chuck

To remove the chuck from a milling machine, you will need a few tools and follow a series of steps. Here is a step-by-step guide to help you remove the chuck effectively:

Step 1: Start by turning off the milling machine and disconnecting it from the power source to ensure safety.

Step 2: Use a chuck key to loosen the chuck by inserting it into the slots on the side of the chuck. Turn the key counterclockwise to release the chuck’s grip on the spindle.

Step 3: Once the chuck is loosened, unscrew it completely using your hand or an adjustable wrench. Turn the chuck counterclockwise until it is fully detached from the spindle.

Step 4: Be cautious while removing the chuck, as it might be heavy depending on its size. Use both hands to support the chuck and prevent any accidental dropping or damage.

Step 5: Place the removed chuck on a clean and secure surface to avoid any scratches or damage. Store it in a safe place or follow the manufacturer’s instructions for proper storage.

Note: Depending on the milling machine model, you may encounter additional steps or specific instructions for removing the chuck. It is always best to consult the machine’s user manual or seek guidance from a professional if you are unsure.

By following these steps carefully, you should be able to successfully remove the chuck from your milling machine. Remember to prioritize safety during the process and handle the chuck with care to avoid any accidents or damage.

Finalizing the Process

Once you have successfully removed the chuck from your milling machine, there are a few final steps you should take to complete the process:

1. Inspect the chuck and the spindle to ensure there are no damages or excessive wear. If you notice any issues, it may be necessary to repair or replace these components before inserting a new chuck.

2. Clean the chuck and spindle thoroughly with a degreaser to remove any dirt, grease, or debris that may have accumulated during the removal process. This will help ensure smooth and reliable operation when you install a new chuck.

3. Apply a light coat of lubricant to the chuck and spindle to reduce friction and facilitate smooth movement. Be sure to use a lubricant that is compatible with the materials of both the chuck and spindle.

4. Carefully align the new chuck with the spindle, making sure that the mounting holes are properly aligned. Gently slide the chuck onto the spindle, taking care not to force it or damage the threads.

5. Use the chuck key or wrench to tighten the chuck securely onto the spindle. Make sure that it is tightened evenly and securely in order to prevent any slippage or misalignment during operation.

6. Once the new chuck is installed, test it by running the milling machine at a low speed. Observe the chuck for any signs of wobbling or abnormal movement. If everything appears to be in order, gradually increase the speed and perform a more thorough test to ensure proper functionality.

By following these final steps, you can ensure that the chuck is securely installed and ready for use on your milling machine. Remember to always prioritize safety and consult the manufacturer’s instructions for specific guidance on removing and installing chucks.

Questions and answers

What is a chuck in a milling machine?

A chuck is a specialized clamp device used to hold a workpiece securely in place during machining operations in a milling machine.

Why would someone want to remove the chuck from a milling machine?

There are several reasons why someone may want to remove the chuck from a milling machine. It could be because the chuck needs to be cleaned or lubricated, or it may need to be replaced with a different type of chuck for a specific machining operation.

What are the steps to remove a chuck from a milling machine?

The steps to remove a chuck from a milling machine may vary depending on the specific machine, but in general, the process involves securing the spindle, removing any retaining screws or bolts, using a chuck removal tool or wrench to loosen the chuck, and finally, lifting the chuck off the spindle.